3D printing has revolutionized the way we approach design and manufacturing, offering unprecedented flexibility and customization. Whether you’re a hobbyist, a designer, or a business looking for rapid prototyping solutions, choosing the right 3D printing technology is crucial. Among the most popular methods are Fused Deposition Modeling (FDM) and Stereolithography (SLA). Each has its unique strengths and applications, but which one is right for you? In this comprehensive guide, we’ll delve into the nuances of FDM and SLA printing technologies to help you make an informed decision.

FDM, or Fused Deposition Modeling, is one of the most widely used 3D printing methods, known for its simplicity and cost-effectiveness. Here’s a closer look at what makes FDM a popular choice:

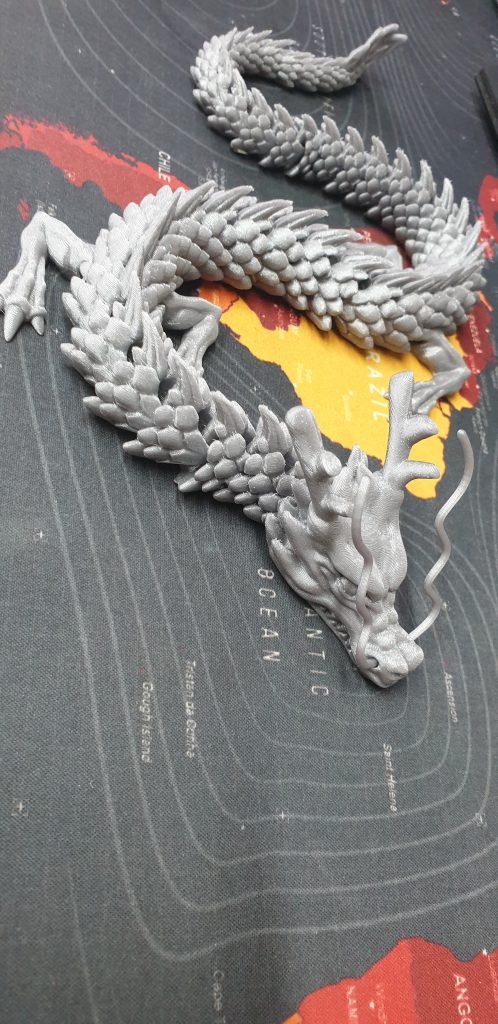

FDM works by extruding thermoplastic filaments through a heated nozzle. The printer lays down the material layer by layer, building the object from the bottom up. This method is straightforward and relatively inexpensive, making it accessible for various applications.

SLA, or Stereolithography, offers a different approach to 3D printing, focusing on precision and high-quality finishes. Here’s what you need to know about SLA:

SLA printing uses a UV laser to cure liquid resin into hardened plastic. The printer traces the object’s cross-section on the resin’s surface, solidifying each layer before moving to the next. This process allows for exceptionally fine details and smooth surfaces.

When deciding between FDM and SLA, consider the following factors to determine which technology aligns with your needs:

| Feature | FDM (Fused Deposition Modeling) | SLA (Stereolithography) |

| Printing Process | Extrudes melted thermoplastic filament layer by layer. | Uses a UV laser to cure liquid resin layer by layer. |

| Cost | Generally more cost-effective. Lower printer and material costs. | Typically more expensive. Higher printer and resin costs. |

| Print Speed | Moderate to fast, depending on the complexity and size of the object. | Slower, especially for detailed or large prints. |

| Surface Finish | Visible layer lines; require post-processing for a smooth finish. | Smooth surface finish right out of the printer; minimal post-processing required. |

| Detail and Precision | Suitable for functional parts but limited in fine details. | Excellent for high-detail and intricate designs. |

| Material Options | Wide variety of thermoplastics, including PLA, ABS, PETG, and composites like carbon fiber. | Various resins, including standard, high-detail, functional, biocompatible, and specialty resins. |

| Durability | Strong and durable prints, suitable for functional parts and prototypes. | Generally less durable than FDM; suitable for detailed models and prototypes requiring high precision. |

| Post-Processing | Requires support removal, sanding, filling, and painting. | Requires support removal, washing, and UV curing. |

| Applications | Prototyping, custom tooling, jigs, educational models, functional parts. | Dental and medical models, jewelry design, miniatures, artistic models, detailed prototypes. |

| Ease of Use | User-friendly, especially with auto-bed leveling and integrated monitoring systems. | Requires careful handling of resin and more complex post-processing steps. |

| Environmental Impact | Options for eco-friendly filaments; generally less wasteful. | Resin disposal requires careful handling; environmental impact depends on resin type. |

| Printer Maintenance | Relatively low maintenance; regular cleaning of nozzles and bed leveling. | Requires regular cleaning and careful handling of resin and curing systems. |

| Print Size | Can print large objects, limited only by printer bed size. | Typically limited to smaller build volumes compared to FDM. |

| Material Properties | Materials like ABS and PETG offer high strength and durability. | Specialized resins can offer high detail, flexibility, or biocompatibility. |

| Usage Environment | Suitable for home, office, and industrial environments. | Typically used in more controlled environments due to resin handling. |

| Learning Curve | Easy for beginners, with many resources and community support available. | Steeper learning curve due to resin handling and post-processing steps. |

| Versatility | Highly versatile, suitable for a wide range of applications. | Best for applications requiring high detail and precision. |

FDM technology has a broad range of applications across various industries due to its versatility and affordability. Here, we’ll explore some real-world examples where FDM has proven to be the ideal choice:

In the manufacturing industry, the ability to rapidly prototype and iterate designs is crucial. FDM’s cost-effectiveness and ease of use make it an excellent choice for creating functional prototypes. For instance, automotive companies often use FDM to develop and test parts before committing to expensive tooling.

A leading automotive manufacturer needed to prototype a new car part with specific durability requirements. Using FDM, they were able to produce several iterations quickly and at a low cost. The use of FDM ABS allowed them to create prototypes that withstood rigorous testing, significantly reducing the time and cost associated with traditional prototyping methods.

Manufacturing processes often require custom tools and jigs. FDM is particularly well-suited for producing these items because of its strength and material variety.

A consumer electronics company utilized FDM to create custom jigs for their assembly line. By using durable materials like FDM PC, they produced jigs that enhanced the efficiency and accuracy of their assembly process. The quick turnaround and low cost were significant advantages, allowing for rapid adjustments and improvements.

FDM is widely used in education for creating models that help in teaching complex concepts. From anatomical models in medical schools to architectural designs in engineering courses, FDM provides a tangible way to bring theoretical concepts to life.

A medical school needed detailed anatomical models for student training. They opted for FDM due to its affordability and the variety of available materials. Using FDM PLA, they created durable models that helped students better understand human anatomy through hands-on learning.

SLA technology excels in applications requiring high precision, fine details, and smooth surface finishes. Here are some examples of where SLA shines:

SLA’s precision and ability to produce smooth surfaces make it ideal for dental and medical applications. This includes creating accurate dental molds and surgical guides.

A dental lab is needed to produce highly accurate dental impressions for custom dental implants. Using SLA, they were able to create detailed models with smooth finishes, ensuring a perfect fit for each patient. The use of SLA high-detail resin provided the necessary accuracy and detail, significantly improving patient outcomes.

The jewelry industry often requires highly detailed models for casting. SLA’s ability to produce intricate designs with fine details makes it perfect for this application.

A custom jewelry designer utilized SLA to create prototypes of intricate pieces. The high precision and smooth surface finish of SLA allowed them to present highly detailed models to clients, leading to a higher approval rate before moving to the casting stage. This process not only saved time but also reduced material waste.

Artists and designers often require models with fine details and a high-quality finish. SLA’s capabilities make it an excellent choice for creating miniatures and other artistic models.

A company producing miniatures for tabletop games chose SLA to create detailed characters and scenery pieces. The smooth finish and high level of detail achievable with SLA enhanced the aesthetic appeal of the miniatures, leading to increased customer satisfaction and sales. Using various SLA resins, they were able to achieve the desired results consistently.

EXCELLENT

When deciding between FDM and SLA, consider the specific requirements of your project. Here are some key points to help you choose:

At 3DRevolution.co.uk, we offer both FDM and SLA printing services to meet a diverse range of needs. Whether you’re developing a functional prototype or creating intricate designs, our team can help you choose the right technology and materials for your project. Visit our services page to explore our offerings and get started on your 3D printing journey.

Post-processing is an essential step in 3D printing, enhancing the quality and functionality of printed parts. Both FDM and SLA prints benefit from post-processing, though the techniques and tools used vary. In this section, we’ll cover the best practices for achieving professional results with your FDM and SLA prints.

FDM prints often require post-processing to improve their appearance and functionality. Here are some common techniques:

Support structures are necessary for printing overhangs and complex geometries but need to be removed once printing is complete.

Sanding helps to smooth the surface of FDM prints, especially if there are visible layer lines.

Filler materials can be used to smooth out gaps and seams in FDM prints.

Painting enhances the appearance of FDM prints, giving them a professional look.

Chemical smoothing can significantly improve the surface finish of FDM prints, particularly for materials like ABS.

SLA prints typically have a finer surface finish out of the printer, but they still benefit from post-processing to achieve optimal results.

Similar to FDM, SLA prints often require support structures that need removal.

SLA prints are often sticky when they come out of the printer due to uncured resin. Washing and curing are critical steps to finalize the print.

For an ultra-smooth finish, sanding and polishing SLA prints can be effective.

Painting SLA prints can add color and protect the surface.

Effective post-processing is key to transforming your 3D prints from good to great. By following these best practices for FDM and SLA post-processing, you can enhance the appearance, functionality, and durability of your prints. At 3DRevolution.co.uk, we provide detailed design guides and support to help you achieve the best results with your projects. Visit our materials page to explore the full range of materials and get started on your next 3D printing project.

As 3D printing technologies continue to evolve, both FDM and SLA are seeing significant advancements that promise to enhance their capabilities and expand their applications. In this final section, we will explore the future trends in FDM and SLA printing technologies, providing insights into what you can expect in the coming years.

FDM technology is continually improving, with developments focused on enhancing print quality, speed, and material versatility.

New advancements in FDM technology aim to significantly increase print speed without compromising quality.

The range of materials available for FDM printing is expanding, offering more options for specialized applications.

Automation and smart features are making FDM printers more user-friendly and efficient.

SLA technology is also advancing, with a focus on improving precision, material properties, and accessibility.

SLA printers are achieving higher levels of precision and detail, opening new possibilities for intricate designs.

SLA materials are evolving to meet the demands of more diverse applications.

Improving accessibility and user experience is a key focus for SLA technology.

At 3DRevolution.co.uk, we are committed to staying at the forefront of 3D printing technology. By continually updating our equipment and expanding our material offerings, we ensure that our clients have access to the latest advancements in FDM and SLA printing. Whether you are looking to create durable prototypes with advanced FDM materials or intricate designs with high-precision SLA resins, we have the solutions to meet your needs.

The future of FDM and SLA printing technologies is bright, with ongoing advancements driving improvements in speed, quality, and versatility. By staying informed about these trends and adopting the latest innovations, you can take full advantage of what 3D printing has to offer. At 3DRevolution.co.uk, we are here to support you with cutting-edge technology and expert guidance. Visit our services page to learn more about how we can help you achieve your 3D printing goals.

Choosing between FDM and SLA printing technologies depends on your specific needs and project requirements. By understanding the strengths and limitations of each, and staying updated on the latest advancements, you can make informed decisions that will enhance your 3D printing projects. Whether you’re looking to create robust prototypes or highly detailed models, 3DRevolution.co.uk is your partner in bringing your ideas to life.

We hope this guide has provided valuable insights into FDM and SLA printing technologies, helping you choose the right method for your next project. For more information and to start your 3D printing journey, visit 3DRevolution.co.uk.

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services