High stiffness, good detail, affordable. PLA is a biodegradable thermoplastic for low-cost, non-functional prototyping. Greater detail than ABS, but more brittle. Unsuitable for high temperatures.

FDM is the most widely available 3D printing process, mainly used for low-cost prototyping and design verification with very fast turn around times.

PLA CHARACTERISTICS:

Accuracy: ±0.2% (with a lower limit of ±0.2 mm)

Max Part Size: 450 x 450 x 470 mm

Layer Height: 100 – 300

Infill Options: 20% Standard – 80-100% High Infill

Wall Thickness: 0.8 mm

Tolerances: ±0.5% with a lower limit of ±0.5 mm (±0.020″)

Strengths | Weaknesses |

|---|---|

Low-cost, fast turnaround times | Limited dimensional accuracy, print layers are likely to be visible |

RECOMMENDED FOR:

✔ Fit & Form Testing

✔ Electronic Enclosures and Cases

✔ Large Models

✔ End User Products

✔ Batch Manufacturing

✔ Architectural Models

NOT SUITABLE FOR:

✘ Jewellery Design

✘ Small and Detailed Art Models (eg. Miniatures and Gaming)

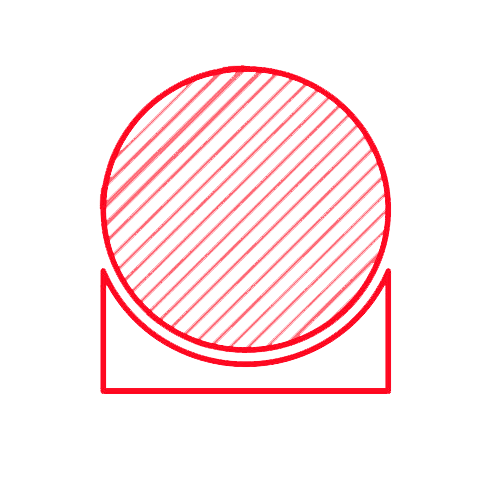

✘ Designs with Large Curved Surfaces (eg. Spherical Objects)

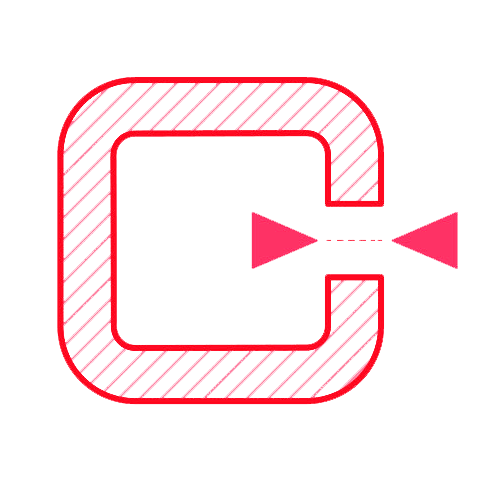

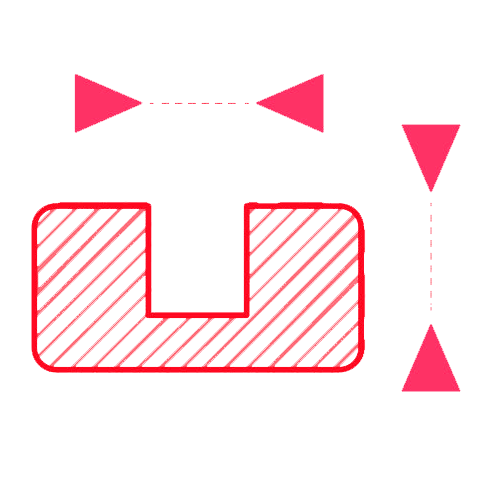

≥ 0.6 mm

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

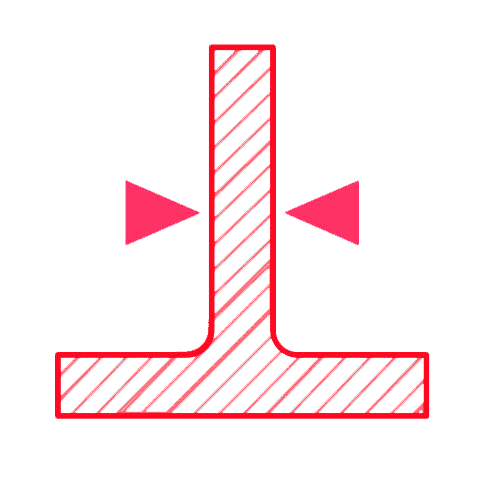

≥ 1.6 mm

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

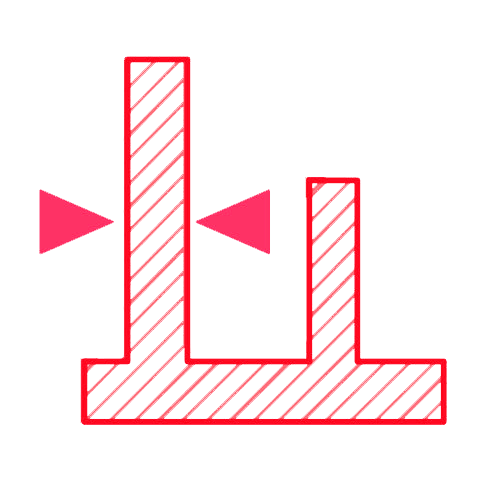

≥ 3 mm

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

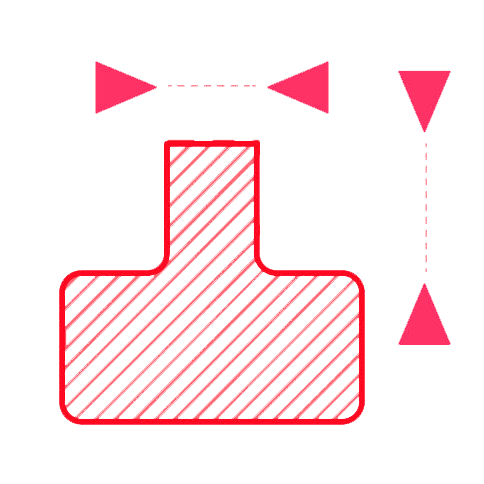

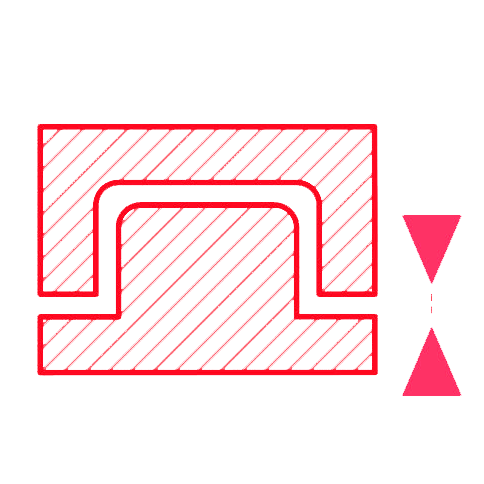

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

≥ 0.4 mm

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Our PLA / PETG / ABS / PC requires supports in order to print overhanging areas. It’s important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.

FDM 3D Printing material

SLA 3D Printing material

PLA, or Polylactic Acid, offers numerous benefits for 3D printing, making it a popular choice for many applications. Its high stiffness provides a strong and rigid structure, which is particularly beneficial for non-functional prototypes.

The material also delivers excellent detail resolution, allowing for precise and intricate designs. Affordability is another key advantage of PLA, as it is one of the least expensive 3D printing materials available, making it ideal for budget-conscious projects. Additionally, PLA has fast turnaround times due to its ease of printing and lower tendency to warp, enabling quicker production cycles and reducing wait times for finished products.

These attributes make PLA an ideal material for low-cost, non-functional prototyping, where speed, detail, and cost-efficiency are crucial.

PLA is versatile and well-suited for various applications across different industries. It is commonly used for fit and form testing, allowing designers to verify the accuracy and functionality of their models before committing to more expensive materials.

PLA is also ideal for creating electronic enclosures and cases due to its good detail and ease of use. Its capability to produce large models makes it a preferred choice for end-user products and batch manufacturing, where consistent quality and scalability are essential.

Additionally, architects often utilize PLA for creating detailed architectural models, benefiting from its precision and affordability. The material’s versatility and reliability make it a valuable tool in both professional and hobbyist settings.

Despite its many advantages, PLA has several limitations that can impact its suitability for certain projects. Its brittleness means it can easily break under stress, making it less ideal for functional parts or items that require high durability. PLA also has lower dimensional accuracy compared to some other materials, which can affect the precision of complex designs.

The visible print layers in PLA models can detract from the aesthetic quality, particularly in designs with smooth, curved surfaces. As a result, PLA is generally unsuitable for jewelry design, small detailed art models, and designs requiring a seamless finish. Understanding these limitations is crucial for selecting the appropriate material for each project.

PLA’s biodegradability is a significant advantage for environmentally conscious projects. Made from renewable resources like corn starch or sugarcane, PLA breaks down more easily than petroleum-based plastics, reducing its environmental footprint. This makes PLA an excellent choice for non-functional prototypes, disposable items, and short-term applications where sustainability is a priority.

However, its biodegradability also means that PLA may not be suitable for long-term or high-stress applications, as it can degrade over time, especially in humid or high-temperature environments. This characteristic should be considered when choosing PLA for projects intended for prolonged use or exposure to harsh conditions.

Infill options for PLA 3D prints range from 20% to 100%, allowing customization based on the desired strength and weight of the final product. A standard infill of 20% is often sufficient for prototypes and models where weight reduction is critical, while higher infill percentages, such as 80-100%, are used for parts requiring increased strength and durability.

The flexibility in infill settings enables users to balance material usage, print time, and mechanical properties, ensuring that the final print meets the specific requirements of the application. Adjusting infill patterns and density can significantly influence the performance and functionality of PLA prints.

PLA generally allows for faster printing speeds compared to materials like ABS and high-detail resin. Its lower tendency to warp and its ease of adhesion to the print bed contribute to a more straightforward printing process, reducing the need for adjustments and recalibrations.

This efficiency translates to shorter print times and quicker project turnaround, making PLA an excellent choice for rapid prototyping and time-sensitive projects. The material’s user-friendly nature and reliability further enhance its appeal for both novice and experienced 3D printing enthusiasts.

PLA prints can be enhanced through various post-processing techniques to achieve a smoother and more polished finish. Sanding is a common method to remove layer lines and imperfections, while painting can add color and improve aesthetics. Polishing with fine-grit sandpaper or a polishing compound can give PLA prints a glossy finish.

However, due to PLA’s brittleness, it is essential to handle the prints carefully during post-processing to avoid damaging the model. Additionally, applying a clear coat or sealant can protect the surface and enhance the durability of the print. These techniques allow for greater customization and refinement of PLA models.

PLA is unsuitable for high-temperature applications, as it has a relatively low glass transition temperature of around 60°C (140°F). Above this temperature, PLA tends to soften, deform, or even melt, which can compromise the integrity of the print.

Therefore, PLA is not recommended for parts that will be exposed to high temperatures or direct sunlight for extended periods. Understanding these temperature limitations is crucial for ensuring the longevity and performance of PLA prints, particularly in applications where heat resistance is a critical factor.

Wall thickness plays a significant role in the strength and durability of PLA 3D prints. Increasing the wall thickness can enhance the structural integrity of the model, making it more robust and less prone to breakage. A minimum wall thickness of 1 mm is recommended for most applications to ensure adequate strength.

For parts that require additional durability, such as load-bearing components or mechanical parts, increasing the wall thickness to 2 mm or more can provide the necessary reinforcement. Balancing wall thickness with overall design considerations helps achieve optimal performance and longevity for PLA prints.

PLA often requires support structures for overhanging areas to ensure print quality and accuracy. These supports provide a temporary foundation for parts of the model that extend beyond the base layer, preventing sagging or collapse during the printing process.

Once the print is complete, the support structures can be carefully removed, leaving a clean and accurate model. It is important to consider the placement and removal of supports during the design phase, as areas in contact with support material may have a rougher finish compared to the rest of the print. Properly designed supports are essential for achieving high-quality PLA prints.

3DRevolution.co.uk offers expert PLA 3D printing services tailored to meet diverse project requirements. With high precision and a wide range of material options, they ensure that every print is of exceptional quality. Their fast turnaround times are ideal for time-sensitive projects, providing quick and reliable results.

Dedicated customer support is available to assist with every step of the process, from design optimization to final delivery, ensuring a seamless and satisfying experience.

By choosing 3DRevolution.co.uk, you benefit from industry expertise, advanced printing technology, and a commitment to delivering outstanding 3D printing solutions.

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services