Our High Detail Resin material has a clean surface finish, sharp details, and excellent flexibility. The material is ideal for small and intricate models, making it ideal for testing your jewelry designs and creating exquisite miniatures. The final result is simple to sand and paint.

HIGH DETAIL RESIN CHARACTERISTICS:

Accuracy: 50 micron XY

Max Size: 192 x 120 x 200 mm

Layer Height: 0.10 microns

Infill Options: 100% Solid

Wall Thickness: 0.5 mm

Tolerances: ±0.5% with a lower limit of ± 0.15 mm (±0.006″)

Strengths | Weaknesses |

|---|---|

Fine features & high detail, smooth, injection mold-like surface finish. | Support marks may be visible on surface, so it’s not recommended for functional parts. |

Before putting your prized creations into production, put them to the test.

The ideal solution for tabletop games and miniatures.

NOT SUITABLE FOR:

✘ Jigs and Fixtures

✘ Functional Prototypes

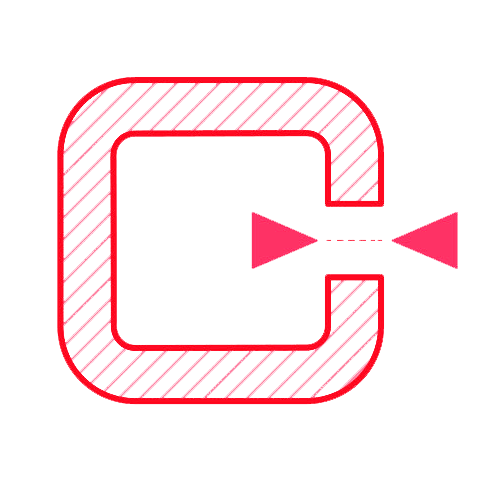

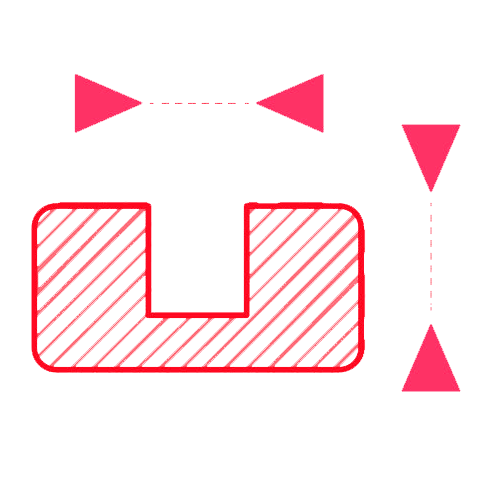

≥ 0.6 mm

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

≥ 1.6 mm

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

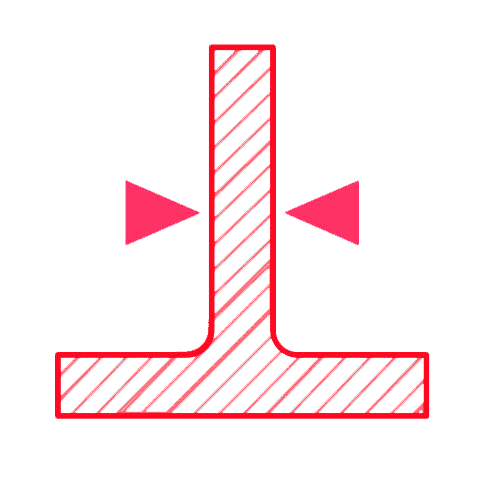

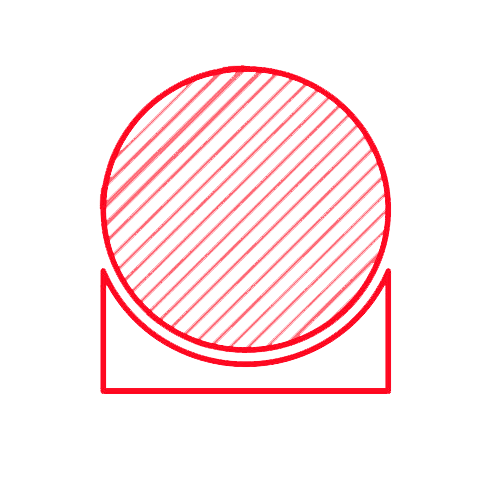

≥ 3 mm

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

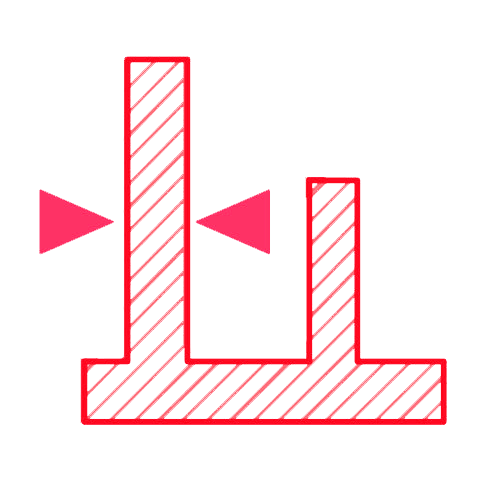

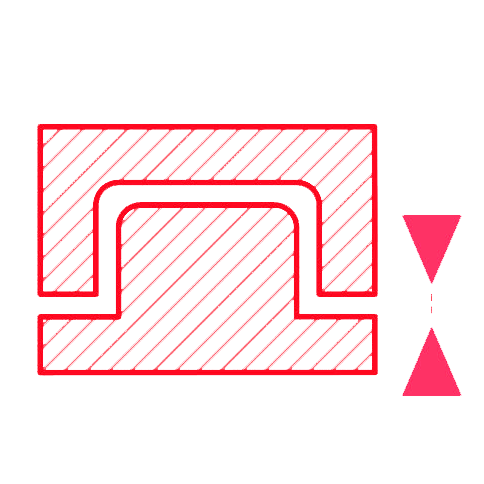

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

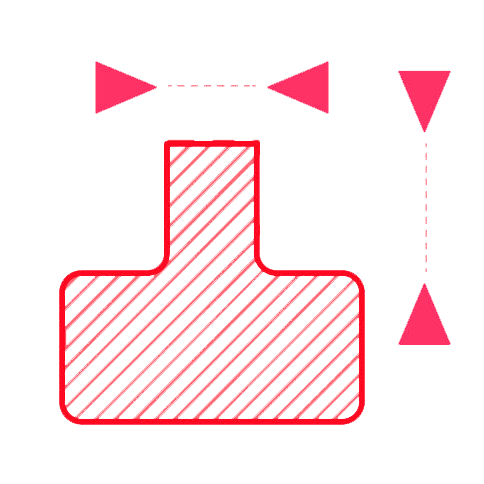

≥ 0.4 mm

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Our PLA / PETG / ABS / PC requires supports in order to print overhanging areas. It’s important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.

FDM 3D Printing material

High Detail Resin printing achieves an exceptional accuracy of 50 microns in the XY plane, ensuring your models are rendered with remarkable precision and detail. This level of accuracy is perfect for intricate designs where fine details are crucial, such as in jewelry prototypes and detailed miniatures, providing a high-quality and professional finish.

High Detail Resin prints boast a strength rating of 95%, making them ideal for detailed and decorative items that require high precision and fine features. While these prints are not intended for functional parts that endure significant mechanical stress, they excel in applications where aesthetic quality and detail are paramount.

Absolutely! High Detail Resin prints are designed to be user-friendly in terms of post-processing. They are easy to sand, providing a smooth surface that is perfect for painting. This allows you to achieve a high-quality finish on your final product, making your models look polished and professional. Whether you’re working on art models, miniatures, or jewelry prototypes, painting High Detail Resin prints can enhance their visual appeal significantly.

High Detail Resin offers several key benefits that make it a top choice for certain types of 3D printing projects:

Despite its many advantages, High Detail Resin has some limitations:

High Detail Resin prints offer a flexibility rating of 20%, meaning they provide some degree of flexibility without compromising the intricate details. This makes the material suitable for applications where some level of flexibility is beneficial, though it remains primarily ideal for detailed and aesthetic parts rather than highly flexible components.

Ordering your High Detail Resin 3D prints from 3DRevolution.co.uk is a straightforward process:

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services