7/10

5/10

5/10

9.5/10

Black

White

The perfect filament for the outdoors!

ASA – short for acrylonitrile styrene acrylate – features many of the same properties as our ABS 3D printer filament – including high strength and little/no warp – but with the added benefit of UV resistance – which means that your prints will be unaffected by weather – especially hot sun – and the outside environment in general. As always, we strive for perfection, and the excellent interlayer adhesion ensures great looking, high performance parts. Overall, ASA is the perfect engineering filament for those prints that need to withstand external environments.

The material is extremely strong and versatile, it the perfect choice for enginering 3D printing project.

PETG CHARACTERISTICS:

Tolerances: ±0.5% with a lower limit of ±0.5 mm (±0.020″)

Max Part Size: 450 x 450 x 470 mm

Layer Height: 100 – 300

Infill Options: 20% Standard – 80-100% High Infill

Wall Thickness: 0.8 mm

Strengths | Weaknesses |

|---|---|

Low-cost, fast turnaround times | Limited dimensional accuracy, print layers are likely to be visible

|

If you’re interested in printing with ASA, it’s helpful to know what it can be used for, as well as some of the reasons you might want to (or not) try your hand at this special filament. It’s a great choice for outdoor projects or for functional prototypes, and if you’re currently printing with ABS, you should consider trying out ASA because they print similarly, but ASA has some extra benefits. Let’s take a deeper look!

RECOMMENDED FOR:

PROS:

CONS:

NOT SUITABLE FOR:

✘ Jewellery Design

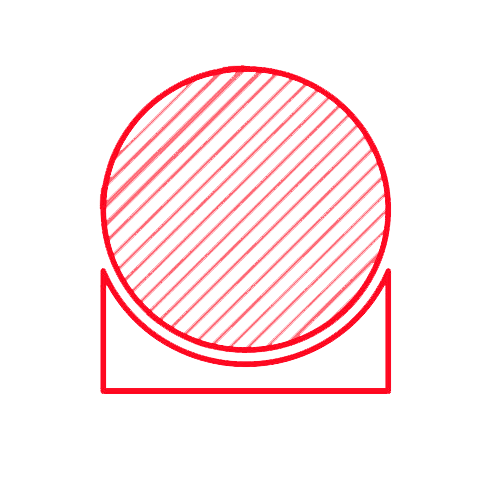

✘ Small and Detailed Art Models (eg. Miniatures and Gaming)

✘ Designs with Large Curved Surfaces (eg. Spherical Object

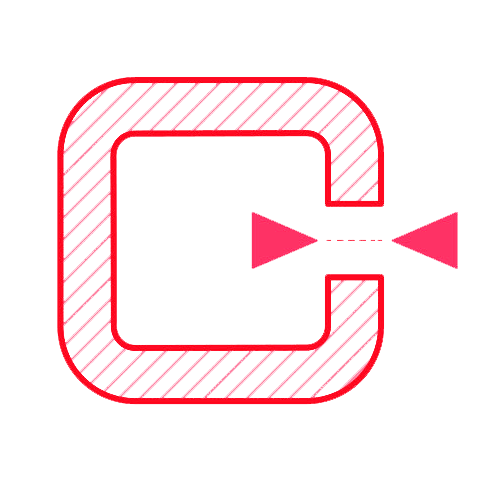

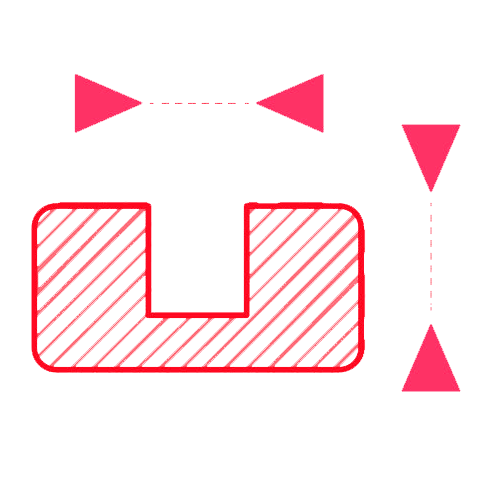

≥ 0.6 mm

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

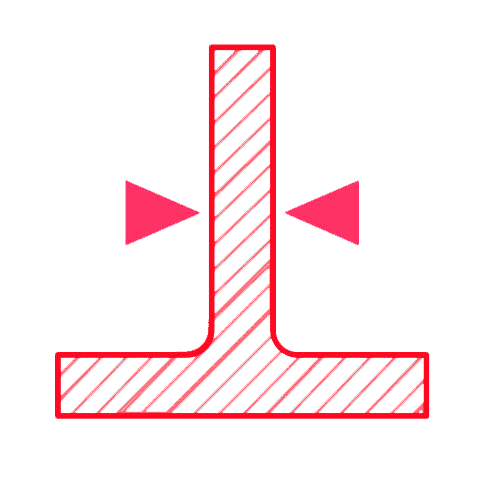

≥ 1.6 mm

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

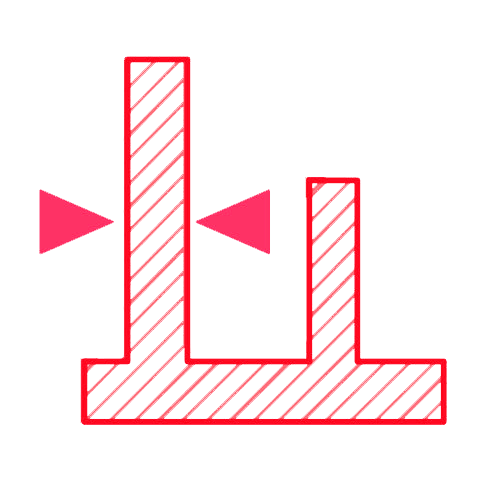

≥ 3 mm

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

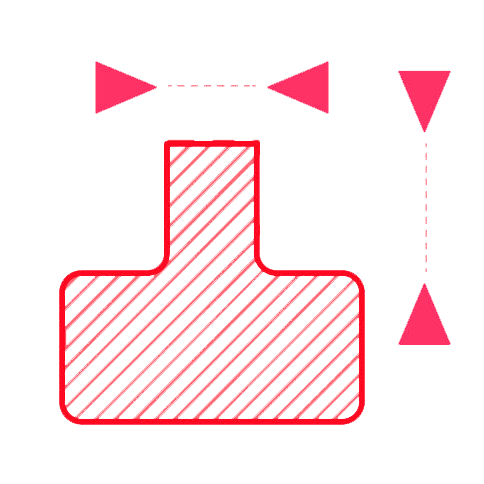

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

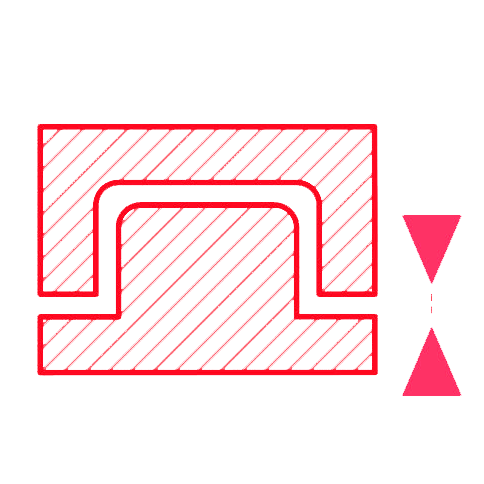

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

≥ 0.4 mm

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Our PLA / PETG / ABS / PC requires supports in order to print overhanging areas. It’s important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.

SLA 3D Printing material

FDM 3D Printing material

FDM 3D Printing material

ASA filament is specifically engineered to withstand harsh outdoor conditions, including high UV exposure, heavy rain, and temperature fluctuations. This makes it an ideal choice for outdoor applications. Unlike other filaments, ASA does not degrade or lose strength when exposed to prolonged sunlight or varying weather conditions.

ASA’s superior UV resistance ensures that prints maintain their color and structural integrity over time, even in extreme climates. For instance, automotive parts made from ASA can endure the constant exposure to sun and rain without becoming brittle or fading. Similarly, exterior signage and outdoor fixtures benefit from ASA’s resilience, ensuring long-term durability and minimal maintenance.

While ASA can be more expensive than some other filaments like PLA or ABS, its superior outdoor performance and durability often justify the cost for many applications. The cost per kilogram of ASA filament generally ranges between $30 and $50, compared to $20 to $30 for ABS and $15 to $25 for PLA. However, ASA’s longevity and reduced need for replacement in harsh environments can lead to overall cost savings in the long run. Its ability to maintain structural integrity and appearance under extreme conditions means fewer reprints and less maintenance, offering better value for projects requiring durability and UV resistance.

To achieve strong and durable ASA prints, follow these guidelines:

Achieving a smooth surface finish with ASA filament involves several post-processing techniques:

While ASA filament offers many advantages, it also has some limitations:

ASA filament is widely used in the automotive industry for its durability and resistance to environmental factors. Common applications include:

To minimize warping when printing with ASA filament, follow these tips:

When designing parts for ASA filament, consider the following:

Yes, ASA’s high strength and durability make it suitable for load-bearing applications. When designing load-bearing parts, ensure:

ASA filament offers excellent chemical resistance, making it suitable for applications exposed to various chemicals. It resists:

Industries such as automotive, construction, outdoor recreation, and electronics significantly benefit from ASA filament due to its exceptional properties:

While ASA filament may have a higher upfront cost compared to some other materials, its long-term benefits can lead to cost savings:

To minimize printing defects such as warping and layer separation when using ASA filament, follow these best practices:

1. Bed Leveling: Ensure the print bed is perfectly leveled to provide a stable foundation for the print. An uneven bed can lead to poor adhesion and warping.

2. Temperature Control: Maintain consistent temperatures with an enclosed build chamber. ASA requires a heated bed (typically around 90-110°C) and a high extruder temperature (220-250°C). An enclosure helps maintain these temperatures and prevents drafts that could cause warping.

3. Quality Filament: Use high-quality ASA filament from reputable suppliers. Poor-quality filament can have inconsistencies that lead to defects.

4. Adhesion Solutions: Apply adhesion aids such as a heated bed with PEI sheets or glue sticks to improve the first layer adhesion and prevent warping.

5. Print Settings: Adjust print settings to match the specifications of the filament. Slow down the print speed if necessary to improve layer adhesion and reduce the likelihood of defects.

Yes, ASA filament can be recycled and reused, contributing to more sustainable 3D printing practices:

ASA filament produces lightweight yet strong parts, offering several benefits:

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services