7/10

5/10

5/10

7,5/10

Black

Red

Ranks as the second most popular 3D printer filament, after PLA. But that just means it’s the second most commonly used. With respect to its material properties, ABS is actually moderately superior to PLA, despite being slightly more difficult to print with. It’s for this reason that ABS is found in many manufactured household and consumer goods, including LEGO bricks and bicycle helmets!

The perfect all-round plastic for your prototyping needs. ABS is widely used across all industries from automotive and aerospace all the way to everyday consumer products. The material is strong and extremely versatile, easy to paint and post process making it the perfect choice for almost any 3D printing project.

HIGH DETAIL RESIN CHARACTERISTICS:

Tolerances: ±0.5% with a lower limit of ±0.5 mm (±0.020″)

Max Part Size: 450 x 450 x 470 mm

Layer Height: 100 – 300

Infill Options: 20% Standard – 80-100% High Infill

Wall Thickness: 0.8 mm

Strengths | Weaknesses |

|---|---|

Low-cost, fast turnaround times | Limited dimensional accuracy, print layers are likely to be visible |

ABS is tough – able to withstand high stress and temperature. It’s also moderately flexible. Together these properties make ABS a good general-purpose 3D printer filament, but where it really shines is with items that are frequently handled, dropped, or heated. Examples include phone cases, high-wear toys, tool handles, automotive trim components, and electrical enclosures.

RECOMMENDED FOR:

✔ Fit & Form Testing

✔ Functional Prototypes

✔ Electronic Enclosures and Cases

✔ Large Models

✔ End User Products

✔ Batch Manufacturing

✔ Jigs and Fixtures

✔ Architectural Models

✔ Enginering parts

NOT SUITABLE FOR:

✘ Jewellery Design

✘ Small and Detailed Art Models (eg. Miniatures and Gaming)

✘ Designs with Large Curved Surfaces (eg. Spherical Objects)

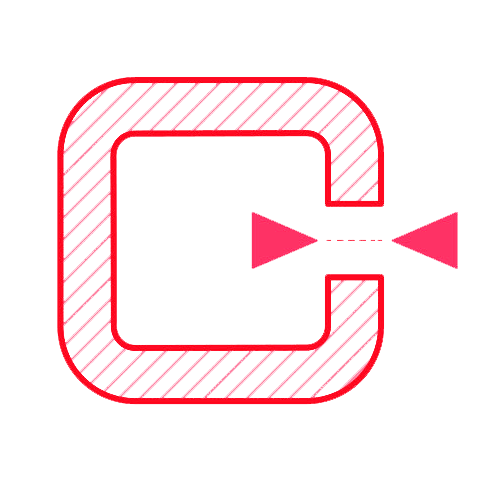

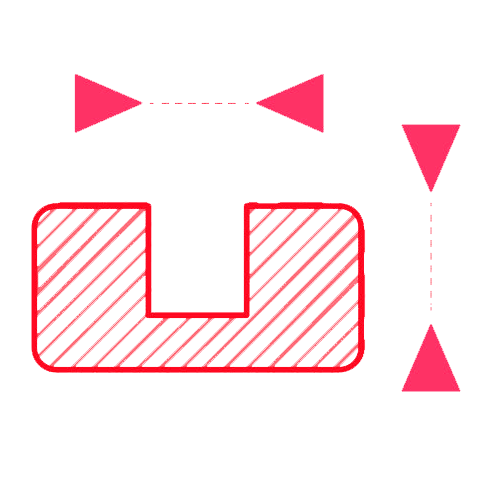

≥ 0.6 mm

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

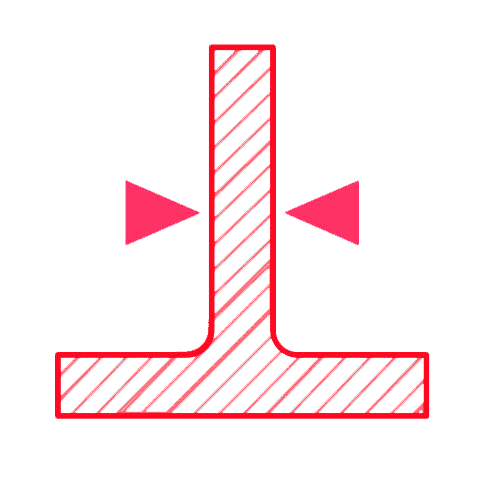

≥ 1.6 mm

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

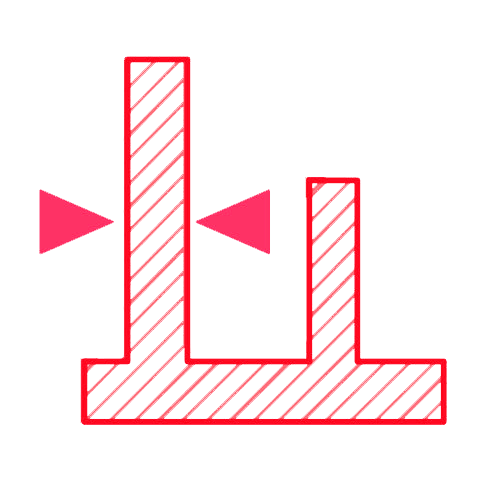

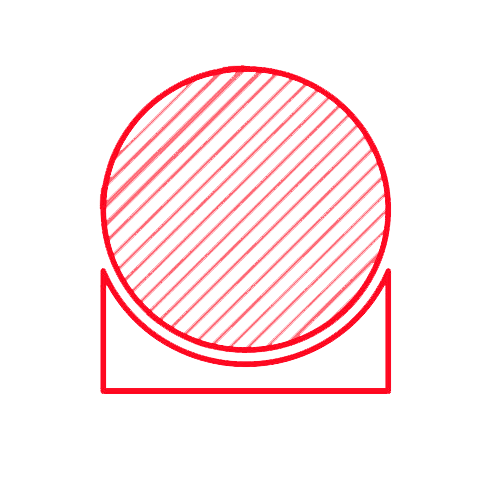

≥ 3 mm

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

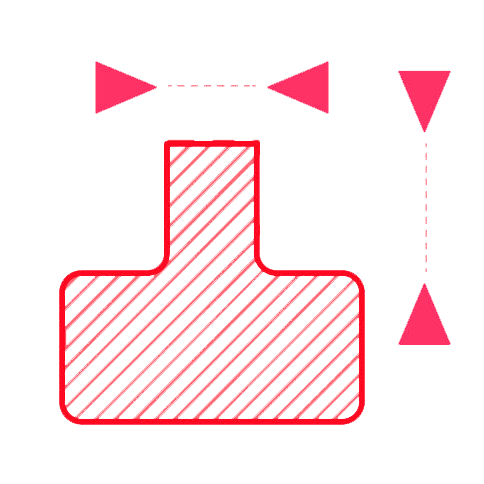

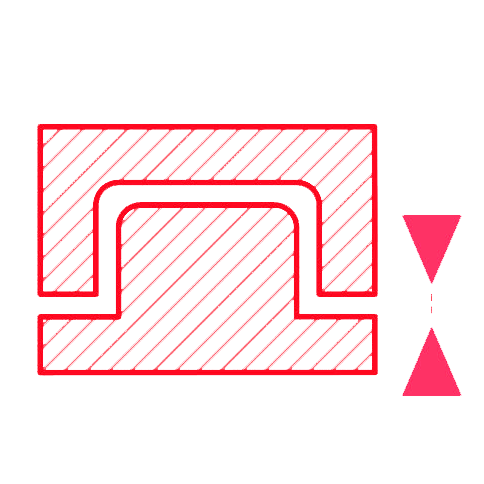

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

≥ 0.4 mm

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Our PLA / PETG / ABS / PC requires supports in order to print overhanging areas. It’s important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.

FDM 3D Printing material

FDM 3D Printing material

FDM 3D Printing material

Choosing ABS (Acrylonitrile Butadiene Styrene) offers several distinct advantages:

When comparing ABS to PLA:

Yes, ABS is suitable for outdoor applications due to its durability and heat resistance. However, it is important to note that ABS can degrade over time if exposed to prolonged UV light. To prevent this, you can apply UV-resistant coatings or paint to protect the material.

ABS prints offer a variety of post-processing options to achieve a polished and refined finish:

ABS, while strong and durable, is not the best material for printing very fine details or intricate designs. Its tendency to warp during cooling can lead to inaccuracies in small features. Moreover, FDM (Fused Deposition Modeling) printing, which is commonly used for ABS, has inherent resolution limits that can affect the quality of fine details. This limitation makes ABS less suitable for applications requiring high precision or intricate surface textures. For such purposes, materials like high-detail resin or PLA, which have lower shrinkage rates and better dimensional stability, are often preferred. Despite its advantages, ABS has some limitations:

To minimize warping when printing with ABS:

Yes, ABS parts can be easily bonded:

ABS parts are strong and durable, suitable for high-stress applications. The exact strength can vary based on print settings, design, and infill percentage. Properly printed ABS parts can withstand significant mechanical stress and impacts.

Absolutely, ABS’s durability and versatility make it an excellent choice for end-user products:

Yes, ABS is recyclable. It can be ground down and reprocessed. However, it may require specialized recycling facilities. While ABS production and disposal have environmental impacts, recycling helps mitigate some of these concerns.

ABS (Acrylonitrile Butadiene Styrene) typically has a higher shrinkage rate compared to materials like PLA (Polylactic Acid), which can lead to issues such as warping and cracking during the cooling process. The shrinkage rate of ABS is approximately 0.7% to 1.5%. This significant shrinkage can cause the printed part to distort, particularly if the print bed is not properly heated or if the ambient temperature fluctuates. To manage this issue effectively, it is crucial to use an enclosed build space to maintain a consistent temperature and reduce drafts. Additionally, fine-tuning print settings, such as bed adhesion techniques (using a brim or raft), can help minimize warping and ensure a successful print.

ABS is renowned for its excellent mechanical properties, including high impact resistance and toughness. This makes it particularly suitable for parts that are subjected to frequent use, mechanical stress, or abrasion. ABS retains its structural integrity well over time, even under harsh conditions. Its durability is a key reason why it is commonly used in automotive components, protective gear, and industrial applications where longevity and resilience are paramount. Despite its robustness, ABS can degrade when exposed to prolonged UV light and certain chemicals, so it’s important to consider the environment in which the printed parts will be used.

ABS’s combination of strength, durability, and ease of post-processing makes it a popular choice for a wide range of consumer products. Common applications include:

Yes, ABS can be effectively dyed or painted after printing, allowing for a high degree of customization. To achieve the best results, it is recommended to follow these steps:

This post-processing capability makes ABS an excellent choice for applications where aesthetic appearance is as important as functionality, such as in prototypes, decorative items, and consumer products.

By leveraging these insights into ABS’s properties and applications, 3DRevolution.co.uk can provide customers with detailed guidance on selecting the right material for their specific needs, ensuring high-quality, durable prints every time.

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services