3D printing has been around for over 30 years, but it is only recently that the printers have become more affordable and accessible. It was first used in the 1980s as a way to create prototypes of high-performance parts. It was a very rudimentary process then, and the materials available were limited. Now, however, there are many different processes used to make 3D printed objects. The technology is still in development—but 3D printing can be used to create almost anything you want!

In recent years, 3D printing has become popular not only as an industrial prototyping method but also as a consumer product that people can use to make unique items or personalized gifts at home. In fact there are even companies who will print your designs for you! This trend towards affordability and accessibility means we’ll be seeing more and less expensive ways to get into this new form of manufacturing in the future.

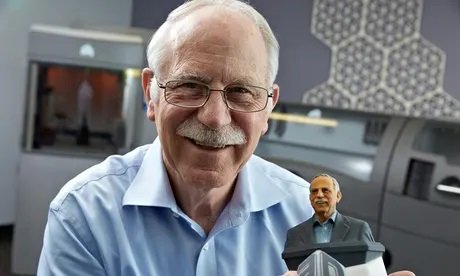

3D printing has been around since the 1980’s. It was originally called “rapid prototyping,” and it was developed by Charles Hull at 3D Systems to produce plastic parts for the aerospace industry. It’s been used in a variety of industries ever since, and has become a household name in the tech world.

The first successful 3D printer was created by Charles W. Hull in 1984. Hull was working at a company called 3D Systems, which makes industrial printers and supplies for other industries like architecture, engineering, and medicine. The company’s first product was a machine that could print out plastic models of objects based on CAD files—these were called “rapid prototypes.”

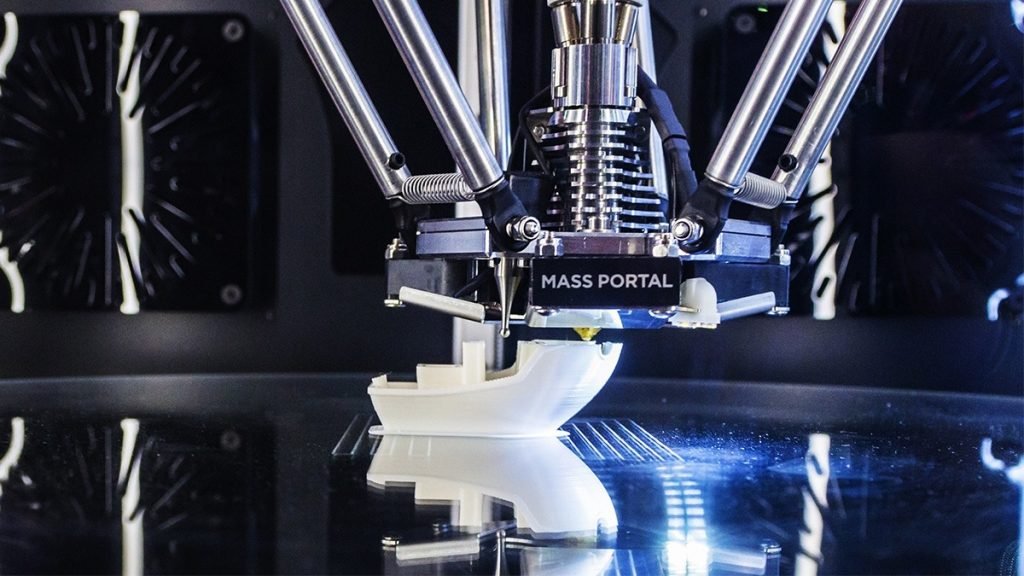

3D printers are machines that use materials (like plastic) and a computer program that tells it how to put those materials together in order to form an object. 3D printers can be used to make anything from small parts that go inside other machines, or entire buildings!

To resume:

1980: First patent by japanese Dr Kodama Rapid prototyping

1984: Stereolithography by French engineers then abandoned

1986: Stereolithography taken up by Charles Hull

1988: First SLA-1 machine

1988: First SLS machine by DTM Inc then buy by 3D system

Charles W. Hull (born May 12, 1939) is an American inventor, entrepreneur, and the co-founder and chief technology officer of 3D Systems. He is best known as the inventor of stereolithography, a form of rapid prototyping technology based on using ultraviolet light to solidify thin layers of photopolymer resin.

Chuck Hull is known as the “Father of 3D Printing,” and for good reason: he truly changed the world when he invented the first commercial printer.

Chuck Hull is the inventor of 3D printing, and he invented it in 1986. He called his invention the stereolithography apparatus (SLA), which used light to solidify liquid polymer resin into a solid form.

After the initial introduction of 3D printing technology, the industry quickly expanded over the next few decades. The first commercial printer was created by Chuck Hull in 1986, who called his invention the stereolithography apparatus (SLA). This printer used light to solidify liquid polymer resin into a solid form.

The 3D printing process was invented in 1987 by Charles Hull, a former general manager at UVP, Inc. He began developing a new process that would allow the company to mass-produce three-dimensional (3D) parts using a computer program. Hull received a patent on October 10, 1986 for stereolithography, the process of creating a three-dimensional object from a computer model by using a photopolymerization process to solidify successive layers of liquid material. Stereolithography was the first rapid prototyping system (RPS) and the STL file format was created by Charles Hull in 1986 for use with the stereolithography process.

Their first foray into the world of 3D printing was a simple eyewash cup. The cup was created using a process called “stereolithography,” which is synonymous with 3D printing. The original creation of the 3D printed Eye Wash Cup is still owned by the Hull family, with Chuck Hull’s wife explaining that it is kept in a safe to ensure its preservation as a historical artifact. The process involves an ultraviolet laser that serves as a light source to cure photopolymer resin into solid plastic.

The process allowed for the creation of objects that were designed on a computer via specialized software and then printed in layers, producing solid objects from what was once just a digital file. Its use as the first-ever 3D printed object is ironic in retrospect, given that 3D printing has gone on to revolutionize so many different industries with its possibilities.

Despite this breakthrough in technological capabilities, it may surprise you to know that this small and seemingly simple item was actually the most advanced thing Crump could have printed at this time. His machine was not equipped to handle larger or more complicated prints; it was limited due to its primitive stage—and even today’s printers are still subject to these same constraints.

It’s hard to believe that 3D printing was only invented in 1984. Now, it’s being used by NASA to assemble spacecraft in outer space, by doctors to create human organs, and by dentists to create dental implants.

In the years since its development, the 3d printing online industry has scaled up and now makes everything from replacement parts for aircraft to fine art. From toys for kids to machine parts. And with innovations in software and hardware, custom 3d printing is no longer limited by what you can model on a computer. As more people become educated on the technology, it’s becoming part of everyday life.

Online 3d printing service is changing the way we think about manufacturing. In decades past, machines like these were used primarily for prototyping and creating one-off parts for products that were already in production. Now, with the advent of additive manufacturing (3D printing), companies can make small batches of parts quickly and cheaply—without having to invest in expensive tooling or waste resources on large runs of parts that may not sell.

This means that 3d printing online businesses can adapt more quickly to customer needs, reduce their environmental footprint by reducing wastefulness in design processes, and get products into customers’ hands faster than ever before!

The future of 3D printing services is only just beginning. As the technology grows and becomes more accessible, it’s set to have a serious impact on the world around us. In fact, many people are calling 3D printing the next industrial revolution.

You may be thinking, “3D printers have been around for some time, but are still a technology in development.” And to you, I say: yes! That’s exactly right. But it’s also important to remember that just because the idea of 3D printing has been around longer than the technology itself, it doesn’t mean we should devalue its potential impact on our world. It’s amazing that we can print something from a computer and if that sounds like something from science fiction, perhaps it is. It’s also present-day reality and its future will be interesting too.

The possibilities are limitless when you think about what can be made with 3D printing: anything!

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services