Industrial thermoplastic with high accuracy, durability and high strength. PC (polycarbonate) is widely used in automotive, aerospace, medical and many other applications. PC offers accuracy, durability and stability, creating strong parts that withstand functional testing. PC also able to withstand temperatures of up to 110°C. It’s also transparent, which explains its use in commercial items such as bullet proof glass, scuba masks, and electronic display screens. Applications include batch manufacturing, jigs, working prototypes and electronic enclosures. Models made with our PC material are easy to sand and post process.

FDM is the most widely available 3D printing process, mainly used for low-cost prototyping and design verification with very fast turn around times.

POLYCARBONATE CHARACTERISTICS:

Tolerances: ±0.5% with a lower limit of ±0.5 mm (±0.020″)

Max Size: 450 x 450 x 470 mm

Layer Height: 100 – 300

Infill Options: 20% Standard – 80-100% High Infill

Wall Thickness: 0.8 mm

Strengths | Weaknesses |

|---|---|

Low-cost, fast turnaround times | Limited dimensional accuracy, print layers are likely to be visible |

Due to its physical properties, PC is an ideal 3D printer filament for parts that need to retain their strength, toughness, and shape in high-temperature environments, such as electrical, mechanical, or automotive components.

RECOMMENDED FOR:

✔ Fit & Form Testing

✔ Functional Prototypes

✔ Electronic Enclosures and Cases

✔ End User Products

✔ Batch Manufacturing

✔ Jigs and Fixtures

✔ Enginering parts

NOT SUITABLE FOR:

✘ Jewellery Design

✘ Small and Detailed Art Models (eg. Miniatures and Gaming)

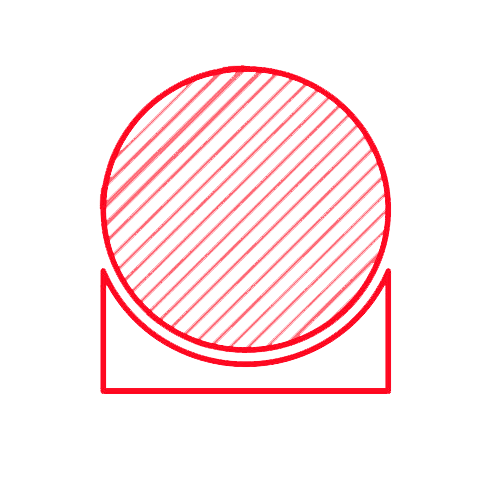

✘ Designs with Large Curved Surfaces (eg. Spherical Objects)

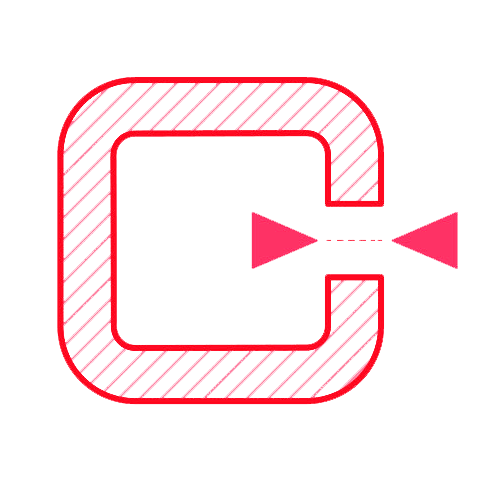

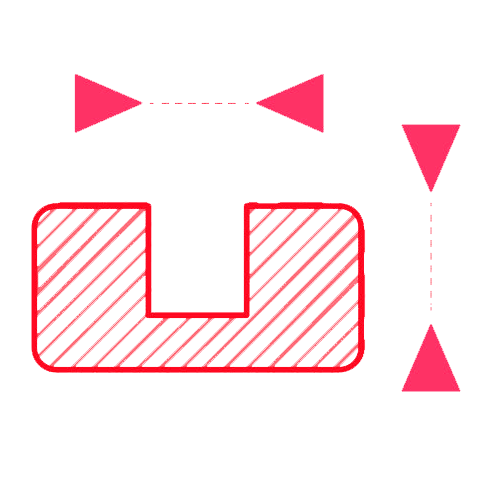

≥ 0.6 mm

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

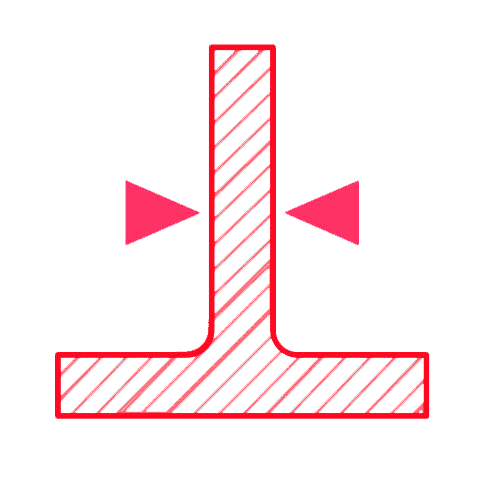

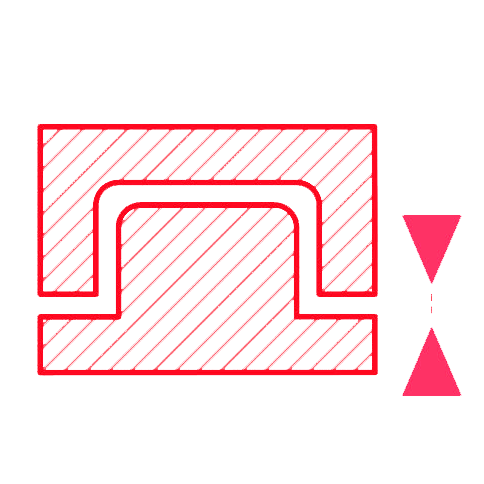

≥ 1.6 mm

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

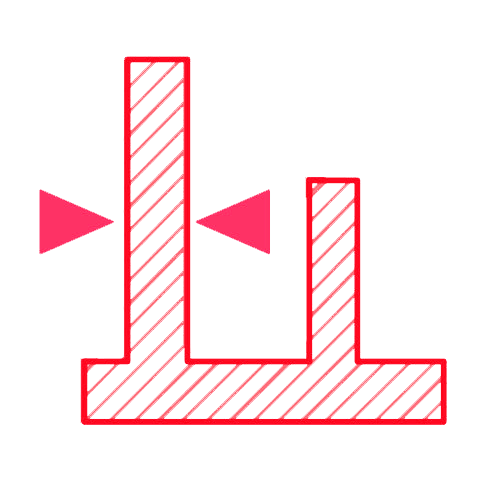

≥ 3 mm

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

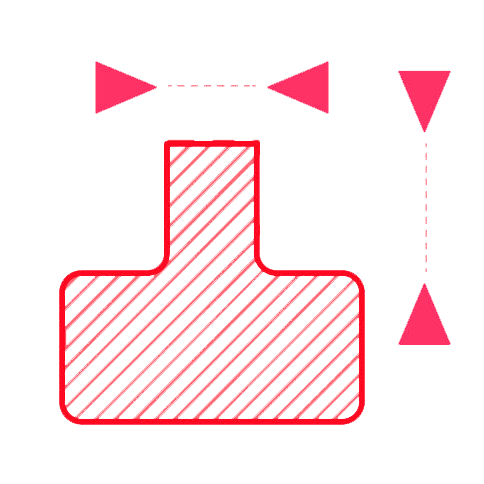

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

≥ 0.4 mm

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Our PLA / PETG / ABS / PC requires supports in order to print overhanging areas. It’s important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.

SLA 3D Printing material

Polycarbonate offers several significant advantages in 3D printing. Its high strength and durability make it ideal for creating robust parts that can withstand heavy use and mechanical stress. Polycarbonate’s impressive temperature resistance, up to 110°C, allows for the production of components that can operate in high-temperature environments without losing structural integrity.

This makes it highly suitable for functional testing and various industrial applications where reliability and performance are critical. Additionally, Polycarbonate’s toughness ensures that printed parts are resistant to impact and wear, extending their lifespan and reducing the need for frequent replacements.

Polycarbonate parts are renowned for their exceptional strength and durability. This material produces components that can endure significant stress and strain, making them suitable for demanding industrial applications.

Whether used in automotive, aerospace, or mechanical engineering, Polycarbonate printed parts maintain their structural integrity and performance over time. This strength makes them perfect for applications requiring long-lasting and reliable components, such as jigs, fixtures, and functional prototypes.

Yes, Polycarbonate prints are highly amenable to post-processing.

The material can be easily sanded to achieve a smooth finish, which is particularly beneficial for parts that require precise dimensions and a refined surface texture. Additionally, Polycarbonate can be machined and polished, allowing for further customization and enhancement of the printed parts. Applying a clear coat can also improve the appearance and durability of the final product, making it suitable for both functional and aesthetic applications.

Polycarbonate 3D prints are versatile and find use in a wide range of applications. Common uses include fit and form testing, where accurate and durable prototypes are needed to evaluate the design of a product. Functional prototypes benefit from Polycarbonate’s strength and temperature resistance, ensuring they perform well in real-world conditions.

The material is also ideal for electronic enclosures and cases, offering protection and durability for sensitive components. End-user products, batch manufacturing, jigs, and fixtures are other popular applications, showcasing Polycarbonate’s ability to produce high-quality, reliable parts for various industrial and commercial uses.

Yes, supports are generally required for Polycarbonate prints, especially for overhanging areas and complex geometries. The use of supports ensures that these sections maintain their structural integrity during the printing process, preventing deformation and warping. It is recommended to design with a minimum unsupported wall thickness of 1.6 mm to achieve the best results.

Proper use of supports and design guidelines helps in producing high-quality prints that meet the desired specifications and performance criteria.

Yes, Polycarbonate can withstand temperatures up to 110°C, making it highly suitable for applications in high-temperature environments.

This heat resistance ensures that Polycarbonate parts do not deform or lose their mechanical properties when exposed to elevated temperatures, making them ideal for use in automotive, aerospace, and industrial applications where high-temperature performance is essential.

Polycarbonate’s transparency is a unique and valuable characteristic, particularly for applications requiring both strength and clarity. This makes it an excellent choice for electronic display screens, providing a clear view while protecting delicate components.

Scuba masks and other safety equipment benefit from Polycarbonate’s strength and visibility, ensuring user safety without compromising on functionality. Additionally, its use in bulletproof glass highlights Polycarbonate’s ability to offer protection and durability while maintaining transparency.

Industries such as automotive, aerospace, and medical are among the most common users of Polycarbonate for 3D printing. In the automotive sector, Polycarbonate is used for parts that need to withstand mechanical stress and high temperatures. The aerospace industry values its strength-to-weight ratio and durability for critical components. The medical field uses Polycarbonate for durable, sterile, and biocompatible parts that must perform reliably under demanding conditions. These industries benefit from Polycarbonate’s robust properties and versatility, making it a preferred material for various high-performance applications.

Yes, Polycarbonate is well-suited for creating end-use products. Its high durability and strength make it perfect for items that need to withstand regular use and environmental stresses. End-use products such as consumer electronics, protective gear, and industrial components benefit from Polycarbonate’s robust nature. Its ability to maintain performance over time ensures that products made from this material are reliable and long-lasting, providing excellent value and performance in everyday applications.

Polycarbonate is indeed recyclable, which enhances its sustainability and environmental benefits. By recycling Polycarbonate, waste is reduced, and the material can be reused in new 3D printing projects or other applications. This recyclability aligns with the growing emphasis on sustainability in manufacturing and 3D printing, contributing to a more circular economy and reducing the environmental impact of plastic waste.

The best way to finish a Polycarbonate 3D print involves several steps. Start with sanding the print to remove any rough edges and achieve a smooth surface. Progress through finer grits of sandpaper to refine the finish. Polishing can then be applied to enhance the surface’s gloss and clarity. For additional durability and aesthetics, applying a clear coat can protect the surface and improve the print’s appearance. This multi-step finishing process ensures that Polycarbonate prints meet both functional and aesthetic standards.

Recommended post-processing techniques for Polycarbonate include sanding, machining, and applying coatings. Sanding smooths out the surface, removing any imperfections from the printing process. Machining allows for precise adjustments and modifications to meet specific design requirements. Applying coatings, such as clear or protective finishes, enhances the durability and visual appeal of the printed part. These techniques ensure that Polycarbonate prints achieve the desired quality and performance.

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services