Carbon fibre is known for being strong, yet lightweight – and now you can 3D print with it!

Carbon Fibre-PETg (CF PETg) is a composite filament – 15% recycled carbon fibre, 85% PETg. This is a dimensionally stable material, which means no warping!

3D printed parts made from CF-PETg feature an attractive, matte black surface finish, with reduced layer visibility for enhanced visual effect. Features of this material include: extreme stiffness, impact resistance, and heat resistance of 75-80°C.

The material is extremely strong and versatile, it the perfect choice for 3D printing project.

CF PETg CHARACTERISTICS:

Tolerances: ±0.5% with a lower limit of ±0.5 mm (±0.020″)

Max Part Size: 450 x 450 x 470 mm

Layer Height: 100 – 300

Infill Options: 20% Standard – 80-100% High Infill

Wall Thickness: 0.8 mm

Strengths | Weaknesses |

|---|---|

Low-cost, fast turnaround times | Limited dimensional accuracy, print layers are likely to be visible

|

Carbon fiber-infused PETG is a doubly impressive material. By infusing fragments of carbon fibers into a PETG polymer base, the mechanical integrity of the PETG blend increases dramatically. Plus, the soft black matte appearance of carbon fiber filaments is just mesmerizing. This makes it an ideal 3D printer filament to use for objects which might experience sustained or sudden stress, like mechanical parts, protective components and high-strength or heat-resistant parts.

RECOMMENDED FOR:

NOT SUITABLE FOR:

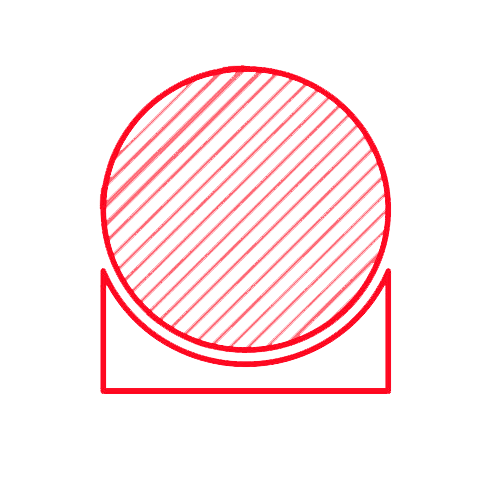

✘ Jewellery Design

✘ Small and Detailed Art Models (eg. Miniatures and Gaming)

✘ Designs with Large Curved Surfaces (eg. Spherical Objects)

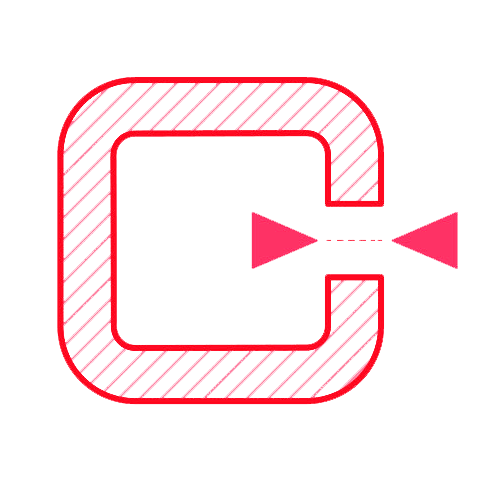

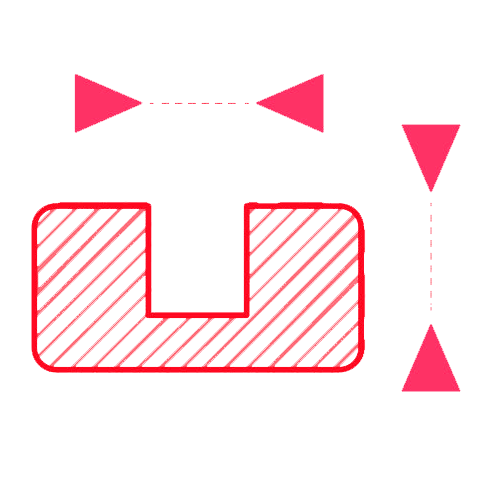

≥ 0.6 mm

Vertical features are often overlooked but they play a very important part in whether or not your print will be successful and how strong the final result will be. We always recommend designing walls with a thickness of at least 1 mm with a minimum viable thickness of 0.6 mm.

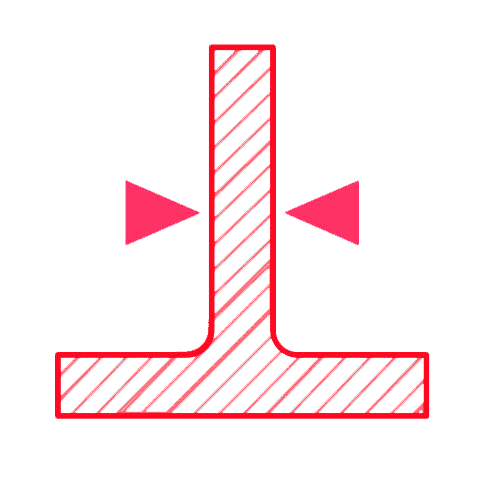

≥ 1.6 mm

In order to achieve the best results we recommend a minimum thickness of 0.6 mm for unsupported walls.

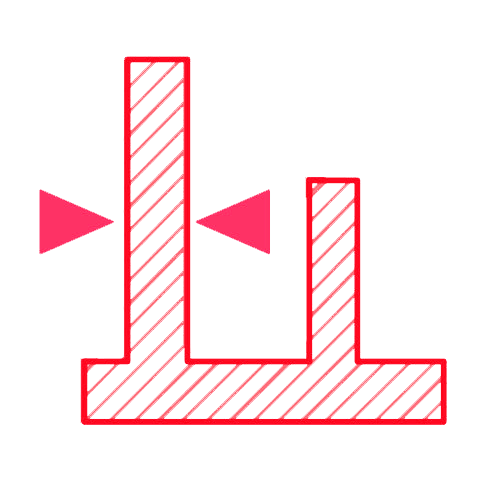

≥ 3 mm

Pins and columns are often used in electronic and end product casings. For best results avoid designing pins with a diameter smaller than 3 mm.

TIP: Adding a chamfer or fillet at the base of your pins will result in much stronger parts.

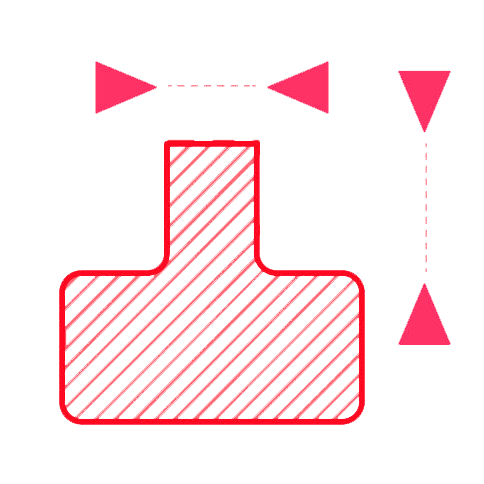

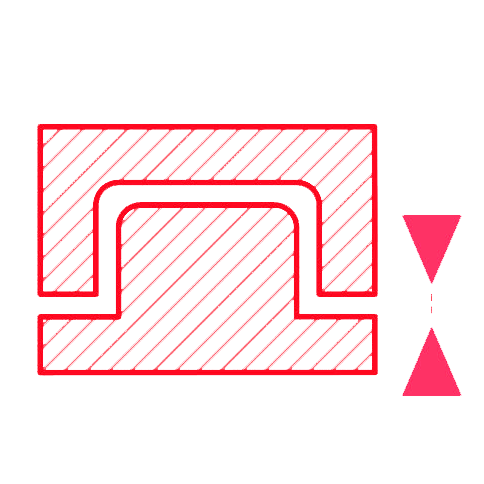

≥ 1.6 mm Thickness

≥ 0.5 mm Depth

Embossed details should have a minimum line thickness of 1.6 mm and a depth of 0.5 mm or higher.

≥ 1.2 mm Thickness

≥ 0.3 mm Depth

Engraved details require a minimum line thickness of 1.2 mm and a depth of at least 0.3 mm.

≥ 0.4 mm

When designing an assembly of parts we suggest leaving a clearance of at least 0.4 mm around moving/sliding parts.

Our PLA / PETG / ABS / PC requires supports in order to print overhanging areas. It’s important to keep this in mind during the design phase since the surface in contact with the support material will exhibit a rougher finish compared with the rest of the model.

SLA 3D Printing material

FDM 3D Printing material

CF PETg, or Carbon Fibre Polyethylene Terephthalate Glycol, is a composite filament combining 15% recycled carbon fibre with 85% PETg. This unique blend makes it ideal for creating strong, lightweight parts with excellent dimensional stability and minimal warping. CF PETg offers:

Extreme Stiffness: The carbon fibre content significantly enhances the material’s stiffness, making it suitable for high-stress applications.

Impact Resistance: It can withstand substantial impact forces, ensuring durability in demanding environments.

Heat Resistance: Capable of enduring temperatures up to 75-80°C, CF PETg maintains its integrity under thermal stress.

Aesthetic Appeal: It yields parts with a sleek matte black finish and reduced layer visibility, enhancing both functional and aesthetic applications.

Durability: Its superior mechanical properties ensure long-lasting performance, even in high-stress environments.

Sustainability: By incorporating 15% recycled carbon fibre, CF PETg contributes to environmental sustainability.

CF PETg stands out among other 3D printing materials due to its unique properties:

Strength and Stiffness: CF PETg surpasses PLA in strength and stiffness, making it more suitable for structural applications.

Heat Resistance: Unlike PLA, which can deform at lower temperatures, CF PETg maintains its shape up to 75-80°C. It also provides better heat resistance compared to ABS.

Surface Finish: CF PETg offers a superior matte black finish with reduced layer visibility, providing a more professional appearance than ABS and PLA.

Dimensional Stability: It experiences minimal warping, ensuring high accuracy for functional prototypes and end-use parts.

Yes, CF PETg’s high heat and impact resistance make it suitable for certain outdoor applications. However, for prolonged outdoor use, it is essential to protect CF PETg parts from extended UV exposure to maintain their mechanical properties and appearance. Coatings or UV-resistant finishes can help extend the lifespan of outdoor CF PETg parts.

CF PETg is versatile and ideal for various industrial applications, including:

While CF PETg is highly versatile, it has some limitations:

Detailing: It may not be suitable for small, detailed art models or intricate designs due to its stiffness and limited dimensional accuracy.

Curved Surfaces: Designs with large curved surfaces might not achieve the desired smoothness.

Jewelry Design: CF PETg is generally too rigid for delicate jewelry pieces, where flexibility is crucial.

CF PETg prints can undergo various post-processing techniques to enhance their visual and functional quality:

Sanding: Smooths out surfaces and removes layer lines.

Painting: Provides color and additional surface protection.

Machining: Allows for precision adjustments and modifications.

Safety: Due to the carbon fibre content, wear protective gear during post-processing to avoid inhaling fine particles.

CF PETg requires supports for overhanging areas and complex geometries. During the design phase, consider support structures to ensure optimal print quality. The surface in contact with support material may exhibit a rougher finish, so proper support planning is crucial.

CF PETg promotes sustainability by incorporating 15% recycled carbon fibre, reducing waste. However, it is not biodegradable and should be disposed of responsibly to minimize environmental impact. Recycling and proper disposal methods are recommended.

To achieve the best quality for CF PETg prints, follow these guidelines:

Design: Ensure a minimum wall thickness of 0.6 mm, with unsupported walls at least 1.6 mm thick, and avoid designing pins with diameters smaller than 3 mm. Adding chamfers or fillets can improve part strength.

Print Settings: Use a nozzle temperature of 240-260°C, a bed temperature of 70-80°C, and appropriate cooling settings.

Support Structures: Properly plan and implement support structures for overhangs and complex geometries.

Post-Processing: Consider sanding, painting, and machining to enhance the final finish and functionality.

Yes, CF PETg’s exceptional strength, stiffness, and heat resistance make it an excellent choice for mechanical parts, protective components, and high-strength or heat-resistant applications. Its properties ensure reliability and durability in demanding environments.

CF PETg produces parts with an attractive matte black surface finish and reduced layer visibility. This professional and sleek appearance makes it ideal for both functional and display purposes. The matte finish also helps to hide minor surface imperfections, enhancing the overall look of the printed parts.

Yes, CF PETg is suitable for batch manufacturing, providing consistent strength, dimensional stability, and a high-quality finish across multiple parts. This makes it ideal for producing small to medium production runs with reliable and repeatable quality.

To get started with CF PETg 3D printing at 3DRevolution.co.uk, follow these steps:

Upload Models: Upload your 3D model files in STL or STP formats on our upload page.

Choose Material: Select CF PETg as your material and configure your print settings.

Instant Quote: Receive an instant quote based on your specifications.

Print and Ship: Once confirmed, your parts will be printed and shipped within 5-10 days. 3DRevolution.co.uk also offers comprehensive customer support, including design guides, troubleshooting assistance, and expert advice to ensure your CF PETg printing projects are successful. Contact us anytime for personalized support and guidance.

Start here if you’d like to discuss a possible project or have a large or complex order which you’d prefer us to review

Upload your existing 3d model for an instant price and order online for FDM and SLA services